Technology brief

The catalyst developed by Luoyang Kechuang Petrochemical Co., Ltd. is suitable for fixed bed low-carbon alkane dehydrogenation to olefin technology. Propylene and isobutylene are produced directly from propane or mixture of propane and isobutane. With this technology, low value-added alkane liquefied gas such as oil and gas fields and refineries can be converted into high value-added propylene and isobutylene products, with small investment and high olefin yield, which provides a new way for refining enterprises to increase production of low-carbon olefins.

Technical characteristics

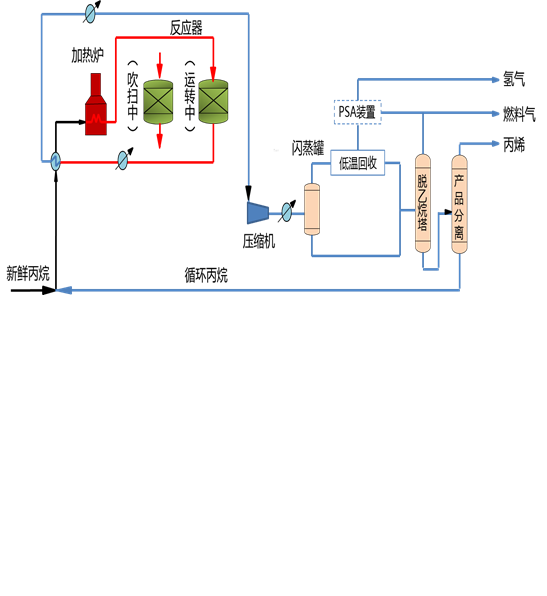

① fixed bed process is adopted, and unreacted propane and isobutane are recycled.

The dehydrogenation performance of the catalyst is stable when using non noble metal catalyst.

③ high one-way conversion rate and low circulation ratio of raw materials reduce investment and operation cost.

Technical index

The technical scheme is flexible, and the production scheme can be adjusted according to the market changes. It can not only produce propylene by propane dehydrogenation, but also produce propylene and isobutylene by mixed feed of propane and isobutane.

When the feedstock is propane, the one-way conversion rate is more than 45%, and the total yield of propylene is more than 85%; when the feedstock is a mixture of propylene and isobutane, the one-way conversion rate of alkane is more than 45%, and the total yield of alkene is more than 85%; the one-way cycle of catalyst is 18 ~ 24min, and the reaction regeneration is continuously switched; the total life of catalyst is 2 ~ 3 years.