Technology brief

The blending components of high octane gasoline are produced by cracking, oligomerization, cyclization, dehydrogenation and other steps on the special catalyst with light hydrocarbons such as refinery dry gas, post ether C4, straight run naphtha, oil field condensate or coking gasoline as raw materials. The modified gasoline has the characteristics of low olefin, low sulfur and high octane number. It is an excellent blending component of clean gasoline. It can be blended with other oil products to produce high-definition clean automotive gasoline that meets the national V and VI standards.

Technical characteristics

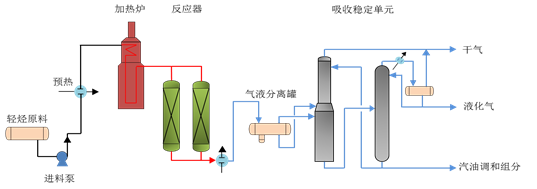

The process technology has a wide range of raw materials, good quality of gasoline products, and the product scheme can be flexibly adjusted according to market changes; the fuel gas is rich in hydrogen, which can be used as a hydrogen source after separation and recovery; the industrial device process is simple, with less investment; the device operation cost and processing energy consumption are low.

When the raw material is the refinery dry gas or liquefied gas rich in olefins, the olefin conversion rate is more than 95%; the olefin selectivity of gasoline is more than 90%, and the Ron of gasoline is more than 92; the catalyst one-way operation cycle is more than or equal to 45 days, and it has been operated for 180 days in a refinery dry gas aromatization unit; the total service life is more than or equal to 3.5 years.

When the feedstock is naphtha with low aromatic potential such as reformer raffinate, pullout oil and coal-based naphtha, the Ron of gasoline product is 85-92, and the dry gas yield is 2-4%; when the feedstock sulfur content is 300ppm, the sulfur content of gasoline product is less than 10ppm; the one-way operation cycle is 30-90 days, and the total service life is ≥ 3.0 years

Technological superiority

Compared with similar technologies:

The catalyst has good activity and aromatics selectivity.

② the catalyst has strong anti coking ability and low dry gas yield.

③ take the lead in adopting the operation technology with pressure

---It saves the rich gas compressor, reduces the equipment cost and the device operation cost.

④ optimized catalyst regeneration technology

---The ratio of regeneration gas to catalyst (volume ratio of recycle gas to catalyst) is reduced by 20-30%, the investment of regeneration part is small, the operation cost is low, and the regeneration efficiency is high.

⑤ high level on-site technical service

---Experienced technicians provide 24-hour on-site technical services.

Industrial application

This technology has been used in more than 40 units at home and abroad, and has achieved good industrial application results.