Technology brief

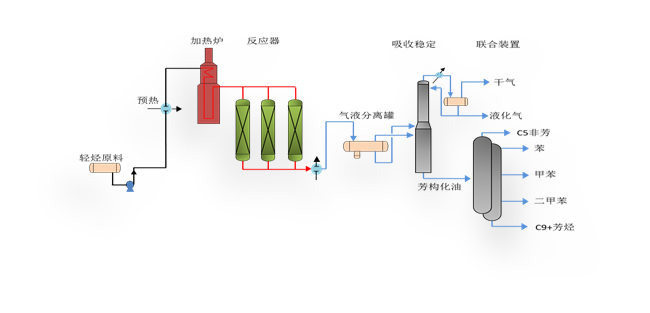

Aromatization of light hydrocarbon to produce aromatics is an advanced technology for aromatization of light hydrocarbon feedstocks (including olefin liquefied gas, naphtha, etc.) under special molecular sieve catalyst and suitable process conditions to directly generate high added value aromatics. This technology has the advantages of less investment and low operating cost. It can not only create economic benefits for enterprises, but also create favorable conditions for enterprises to develop into the chemical industry.

Technical characteristics

Compared with the reforming technology, the aromatics yield is not limited by the potential aromatics content of the feedstock, and the feedstock generally does not need pre fractionation and refining, so it has a wide range of applications. Coking gasoline, straight run gasoline, oil field condensate, reformer topping oil, reformer raffinate oil, cracked gasoline and olefin liquefied gas can be used as raw materials for aromatization.

Using this aromatization technology, when the raw material is alkene rich liquefied gas (alkene content > 50%), the content of aromatics in the liquid phase product is close to 100%, and aromatics extraction is not required; the single-way aromatics yield is more than 48.2%, and the BTX yield is more than 42.2%. Catalyst one-way operation cycle ≥ 20 days, total life ≥ 3.0 years.

When naphtha is used as raw material, the one-way aromatics yield and BTX yield are 35.0% and 32.0% respectively; the one-way operation cycle of catalyst is 20-30 days and the total service life is ≥ 3.0 years.

The generated fuel gas is rich in hydrogen, which can be used as a hydrogen source after separation.

Technological superiority

① aromatization temperature is relatively low

The advanced catalyst forming and modification technology enables the reaction to be carried out at a relatively low temperature. In the aromatics production scheme, the reaction temperature is 30 ℃ ~ 50 ℃ lower than that of other technologies, and the reaction energy consumption is significantly reduced; the requirements of lower reaction temperature for equipment strength are correspondingly reduced; meanwhile, the dry gas yield is relatively low.

(2) unique reaction heating technology

The aromatization of naphtha with alkane as the main feedstock is a strong heat absorption process. The unique reaction heat supplement technology can not only save the intermediate heater, reduce the investment, but also reduce the energy consumption of the unit.

Industrial application

The process technology has been verified in domestic plants of 10000 tons and above, and good application results have been obtained.