Technology brief

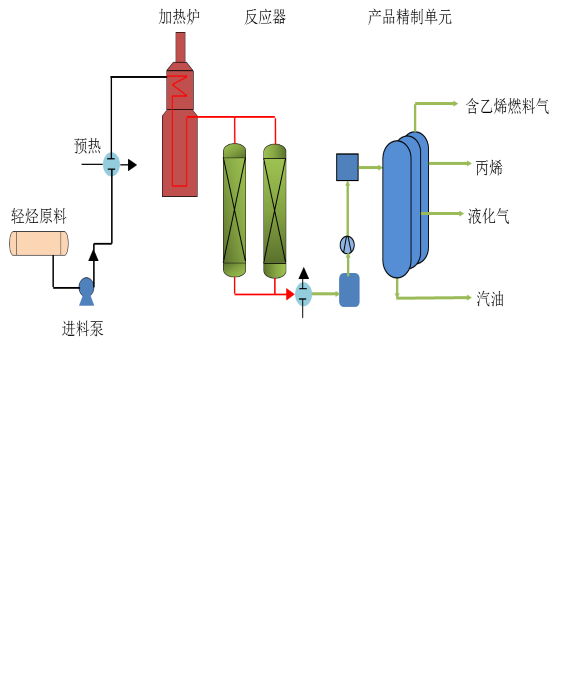

As a new technology developed in recent years, light hydrocarbon catalytic cracking technology has the advantages of both steam cracking and catalytic cracking. This technology is of great significance for energy saving and consumption reduction of petrochemical plants as well as meeting the growing demand for low-carbon olefins, and has opened up a new process route. The light hydrocarbon cracking technology developed by Luoyang Kechuang Petrochemical Co., Ltd. takes C4 ~ C8 light hydrocarbon or straight run naphtha and coal-based naphtha rich in olefins as raw materials. On the special catalyst, light hydrocarbon components can be selectively converted into blending components of ethylene, propylene and high octane gasoline.

Technical characteristics

Compared with the traditional steam cracking technology, the light hydrocarbon catalytic cracking technology has the advantages of low reaction temperature, low process energy consumption, wide source of raw materials and flexible adjustment of product distribution; compared with the catalytic cracking technology, the cracking depth is deep and the yield of ethylene and propylene is high. In addition, the technological process is simple and the investment is small.

When the feedstock is C4 liquefied gas (butene content ≥ 60%), the yield of ethylene + propylene is more than 40%, and the yield of gasoline is about 15-20%

Industrial application

The technology has been running continuously in a plant in Shandong Province.